Mud Mixing Hopper

As a drilling mud hopper manufacturer, the BWSLH series Mud Mixing Hopper produced can be widely used in oil drilling solids control, trenchless excavation and so on. It can be used as a dosing hopper in the chemical industry, can be customized as single mud hopper, double mud hopper, etc.

Email

As a drilling mud hopper manufacturer, the BWSLH series Mud Mixing Hopper produced can be widely used in oil drilling solids control, trenchless excavation and so on. It can be used as a dosing hopper in the chemical industry, can be customized as single mud hopper, double mud hopper, etc.

Mud Mixing Hopper is composed of a venturi tube, a hopper, an electric control base, and a centrifugal pump. The main function of the mud hopper is to hold all the materials mixed into the mud. The main function of the centrifugal pump is to power the mud hopper in order to make the mud move in the equipment. The electric control base is an device used to control the working state of the mud hopper. It is mainly used to connect the pipeline of centrifugal pump and the mud tank.

As a supporting equipment of oil drilling solids control equipment, the Mud Mixing Hopper is mainly used to effectively configure the weighted drilling fluid, so that the density, viscosity, water loss and other functions of the drilling fluid can be appropriately improved. The combined working effect of Mud Mixing Hopper and shear pump is better. The design of the Mud Mixing Hopper has single or double structures, which can be specifically determined according to the amount of drilling fluid to be processed. When the amount of drilling fluid is large, a double jet mud mixer is required.

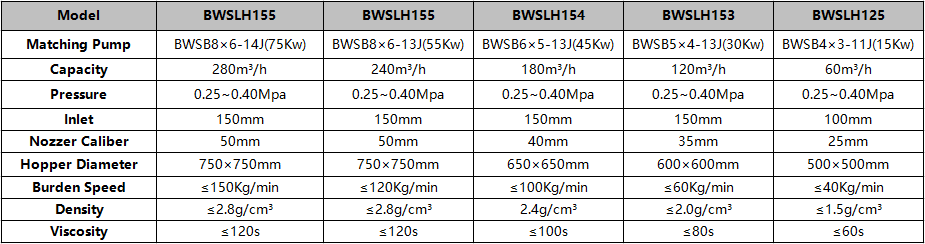

Mud Mixing Hopper Model and Parameters

Feedback Form

For any information needed, please fill the below table or send the request to our Company Email: brightway@bwwell.com for details. We will feedback at the soonest!

Email: brightway@bwwell.com

WhatsApp: +8615091866932