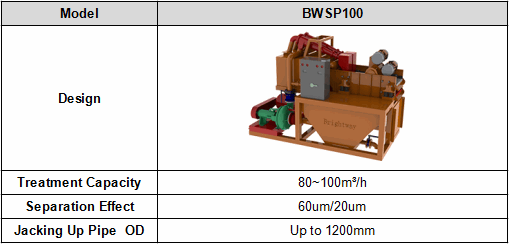

BWSP-100 Desanding Plant is designed for Bored piling construction and diaphragm wall construction. The capacity is up to 100m³/h.

Desanding Plant is small type separation plant for matching with Rotary Drilling Rig in piling construction. And the capacity is 40-100m³/h. Desanding plants are employed to remove soil particles in drilling muds and support slurries used in foundation engineering. They can be either water-bentonite, water-polymere, or water-cement and bentonite suspensions.

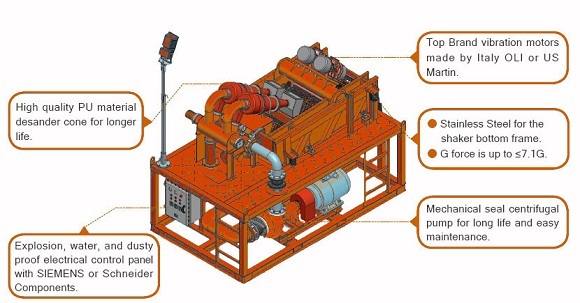

Desanding Plants main components includes: shale shaker with coarse and fine screens, storage tank of the coarse screen, cyclone with cyclone feeder pump for removing fine particles from the suspension, dewatering screens for abstracting further water from the solids dis-charged by the cyclone.

Brightway BWSP-100 Desanding Plant can be used in the Bored piling construction and diaphragm wall construction, and the capacity is up to 100m³/h. The main components includes: coarse screen for intercepting stones larger than 10 mm; storage tank of the coarse screen cyclone with cyclone feeder pump for removing fine particles from the suspension dewatering screens for abstracting further water from the solids dis-charged by the cyclone.

For any information needed, please fill the below table or send the request to our Company Email: brightway@bwwell.com for details. We will feedback at the soonest!

Brightway Solids Control Co.,Ltd