HDD350 series mud recycling system is consists of BWZS103P shale shaker, BWZJ102-6N mud cleaner, BWSB centrifugal pump, BWSLH jet mud mixer, BWJBQ mud agitator and other mud equipment. BWHDD350 series mud recycling system is designed for the 160-200 tons horizontal directional drilling rig and can match the 1200-1500L/min mud pump in trenchless projects. The design capacity is 80m³/h (350GPM). Know more: BWHD-350 Mud Recycling System Application and Case

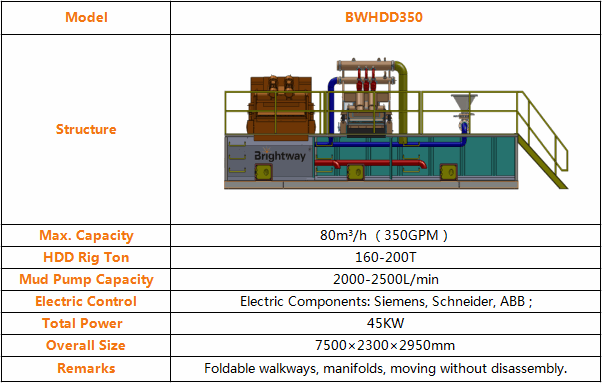

BWHDD350 Mud Recycling System Parameter

BWHDD350 Mud Recycling System Structure

1. Combination of screening, desanding and desilting. Compact structure, easy for transportation and small footprint.

2. Foldable handrail and walkway, easy for assembly.

3. Fast connection for the equipment, easy for dis-assembly, saving time and labor.

4. Same cyclones process with Derrick’ s and interchangeable with each other. High wear-resistance and long life span under normal service conditions (more than 3,800 hours).

5. Explosion-proof lights, safe for operation, meeting the needs of continuous construction.

BWHDD350 Mud Recycling System Features

1. Each project and rig is different, so is the solids control. Brightway Mud Recycling System is designed and Manufactured according to the feature of Horizontal Directional Drilling Rig.

2. Group works of rig Engineering and Systems closely with rig designers, contractors, operators and shipyards can assess their unique specifications.

3. Optimum solids control programs to meet the specific cost, operational and environment requirements.

4. Strong adaptability of solid-liquid separation of different geological layers, improving the operating efficiency and saving the cost of the recycled mud.

According to different geological conditions and customers’ requirements, Brightway can design and manufacture mud recycling systems in different models to match with GD Drilling Rig.

Feedback Form

For any information needed, please fill the below table or send the request to our Company Email: brightway@bwwell.com for details. We will feedback at the soonest!

Email: brightway@bwwell.com

WhatsApp: +8615091866932