BWSP-400 Separation Plant is designed for tunneling industry. It can be matched with the tunnel boring machine (TBM). The capacity is up to 400m³/h (2000GPM). The BWSP-400 Separation Plant is of modular system construction. It is designed for the treatment of large amounts of all kinds of slurries used in common construction techniques. Know more:

BWSP-400 Separation Plant Application and Case

The BWSP-400 Separation Plant consists of a BWSP2-P coarse sieve module fitted with a coarse vibrating screen for removal of large particles, a BWZJ1S10N desanding module fitted with one clone and a fine vibrating screen BWZS-3P and a barely of fine cyclones for subsequent separation of fines.

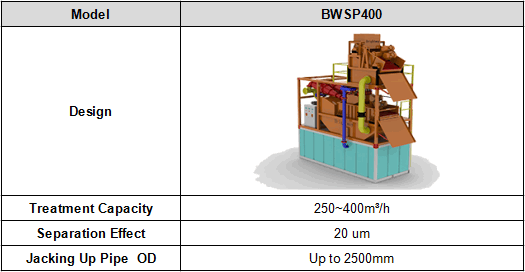

BWSP-400 Separation Plant Parameters

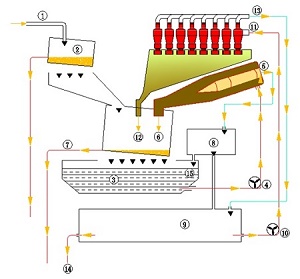

BWSP-400 Separation Plant Working Principle

1. From the coarse sieve the slurry let into the plant will drop into a collecting trough to then be conveyed through a connecting pipe to the desanding module.

2. where a pump unit with one cyclone of 10’’ in diameter removes sand from the slurry and another pump unit with ten cyclones of 4" in diameter carry out a subsequent refinement as desired.

3. The slurry out from the underflow plug transferred through the lead pipe flow into the fine shaker screen to reprocess.

4. The slurry out from the overflow pipes drop into the slurry collection tank and become available.

Brightway Separation Plant Features

Brightway separation plants are adapted to the requirements of the tunnelling process and separate the slurry suspension completely from the solid particles consisting of gravel, stone and sand in various grain sizes. Optimized for the treatment of microtunnelling slurries and tunneling slurries.

1. Powerful G-forces with double-deck shakers; efficient and stable separation,

2. Well-designed cyclones for a better fine-cut even under difficult conditions, Powerful performance;

3. Field-proven screen system-durable and adjustable; Capable of handling high solids loads;

4. Modular design, easy setup and operation; ensures high speed and low costs for assembling and dismantling.

As a professional Separation Plant Manufacturer in China, Brightway can designed and manufacture diffirent Model Separation Plant : BWSP500 (500m3/h),BWSP1000 (1000m3/h),BWSP1500 (1500m3/h), BWSP3000 (3000m3/h),BWSP4000-20 (4000m3/h), BWSP6000-20 (6000m3/h), for Tunnel Boring Machine with outer diameter such as 2000mm, 2500mm, 4200mm, 6000mm, 10000mm,15000mm,17000mm.

Feedback Form

For any information needed, please fill the below table or send the request to our Company Email: brightway@bwwell.com for details. We will feedback at the soonest!

Email: brightway@bwwell.com

WhatsApp: +8615091866932