Sludge Dewatering Centrifuge

Brightway is a manufacturer and supplier of Sludge Dewatering Centrifuge used in solids control. It can produce and supply: decanter centrifuges for oil drilling, drilling fluid centrifuges, sludge dewatering centrifuges, high-speed centrifuges, medium-speed centrifuges, low-speed centrifuges, etc. They can be applied to the fields of drilling mud treatment in oilfields, mud dewatering in piling, mud water separation in desand plants and in tunneling construction sites.

Email

Brightway is a manufacturer and supplier of

Sludge Dewatering Centrifuge used in solids control. It can produce and supply: decanter centrifuges for oil drilling, drilling fluid centrifuges, sludge dewatering centrifuges, high-speed centrifuges, medium-speed centrifuges, low-speed centrifuges, etc. They can be applied to the fields of drilling mud treatment in oilfields, mud dewatering in piling, mud water separation in desand plants and in tunneling construction sites.

The characteristics of Brightway sludge dewatering centrifuge

Brightway centrifuges are decanter centrifuges, which can be widely used in the field of oilfield drilling solids control to process drilling fluids, as well as in the field of municipal projects to dewater sludge. The main parts and components of the durm are made of corrosion-resistant stainless steel; the screw conveyor has special anti-wear design, which can be coated with hard alloy protective layer or inlaid with hard alloy pieces. The angles of the durm vary; the control system with differential speed and torque can be automatically adjusted with the change of the material concentration and flow. The centrifuge can concentrate and dehydrate sedimentation and sludge that are difficult to process.

Currently Brightway has developed a variety of combinations of sludge dewatering centrifuge drums and screw propellers:

1. Two AC variable frequency motors and two frequency converters are used to drive the drum and screw respectively, and the differential speed can be adjusted by adjusting the speed of the auxiliary motor. In addition, the differential speed automatic control function is added;

2. An AC frequency conversion motor and a frequency converter are used to drive the drum, and a hydraulic motor (frequency conversion) with an independent hydraulic pump drives the screw, and the differential speed is adjusted by adjusting the flow rate of the hydraulic pump. The differential speed can be adjusted automatically according to the load. Customers can freely choose configuration according to budget and work conditions.

Advantages of Brightway Sludge Dewatering Centrifuge:

1. The amount of chemicals used in the centrifuge will be significantly reduced, because due to high separation efficiency the centrifuge can efficiently separate fine particles;

2. Maintenance is simpler, and fewer maintenance services are required;

3. It can be widely used in the treatment of river silt;

4. It can save the water resources needed to clean the equipment;

5. It is easy to install and occupies a smaller area;

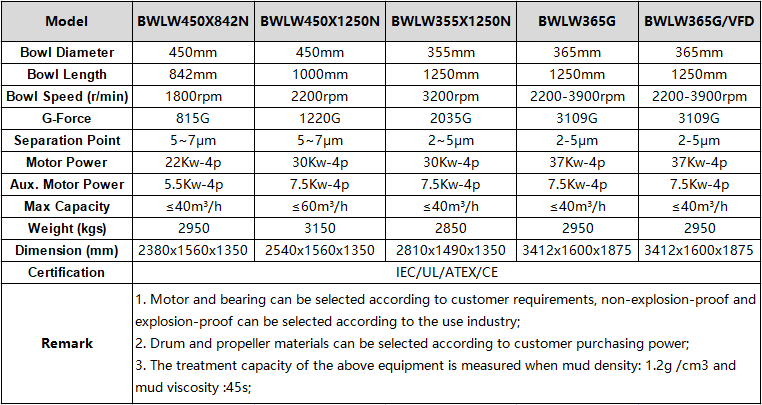

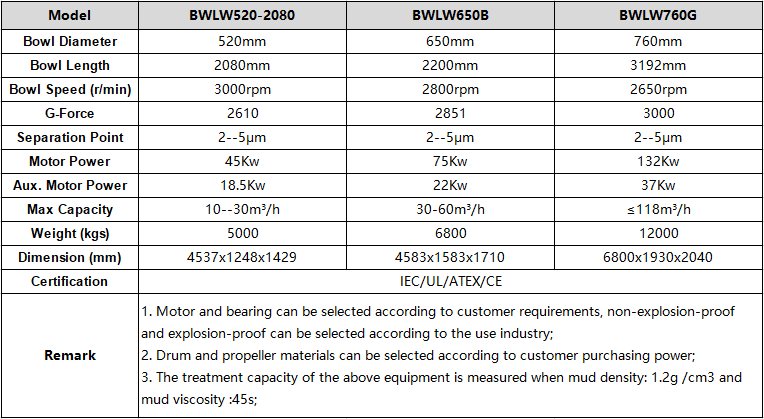

Brightway Sludge Dewatering Centrifuge Parameters

Feedback Form

For any information needed, please fill the below table or send the request to our Company Email: brightway@bwwell.com for details. We will feedback at the soonest!

Email: brightway@bwwell.com

WhatsApp: +8615091866932