Desander and Desilter

Brightway is a professional manufacturer of desanders and desilters. It designs and produces different specifications of desanders and desilters for customers all year round. The current business fields include: oil drilling, trenchless excavation, tunneling and other fields of mud treatment.

Email

Brightway is a professional manufacturer of

desander and desilter. It designs and produces different specifications of desander and desilter for customers all year round. The current business fields include: oil drilling, trenchless excavation, tunneling and other fields of mud treatment.

Desanders and desilters can also be called mud cleaners. A mud cleaner is a combination of a

shale shaker, a desander and a desilter for drilling fluid treatment. The mud cleaner is the primary and secondary purification equipment in the solid control system. It processes and separates the large amount of drilling cuttings carried by the drilling fluid when the fluid is returned from the well. Then the mud enters the next separation equipment. The performance of the mud cleaner directly affects the performance of the lower-level separation equipment. After the drilling mud is processed by the shale shaker, the solid particles become smaller and the content of particles decreases, so further purification of the mud is required. The drilling mud is pumped from the tank to the desander via the slurry pump. After being processed by the desander, most of the solid particles with diameters larger than 47 microns are discharged and fall on the underlying screen. After being sieved and discharging to the tank, the mud will be transported to the desilter. At this time, most of the solid particles with diameters larger than 15 microns are discharged and fall on the underlying sieve. The mud is sieved and conveyed. Most of the mud solid particles desilter tank have diameters less than 15 microns after being processed by the desilter, which is fully ready for the further processing by the

decanter centrifuge.

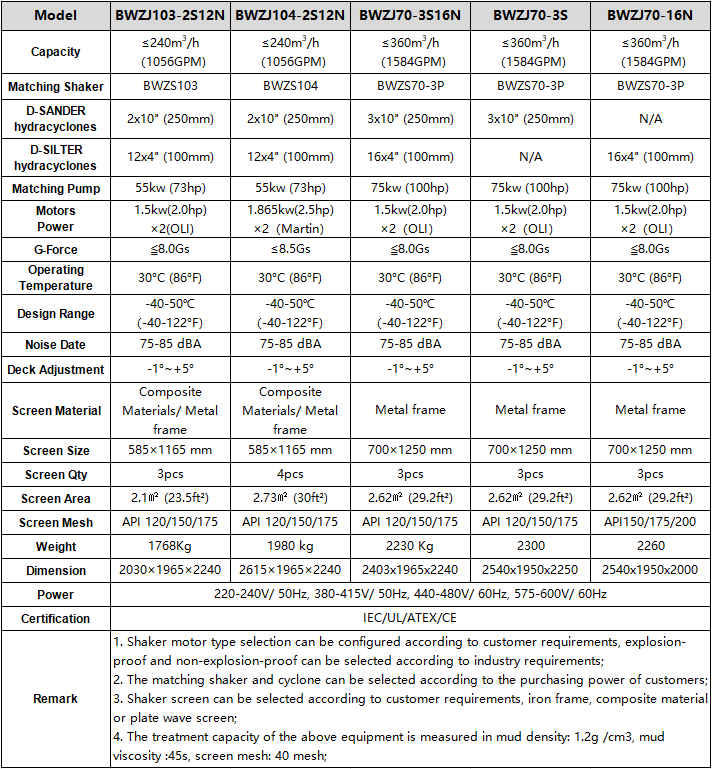

Desander and Desilter Model and Parameters

Feedback Form

For any information needed, please fill the below table or send the request to our Company Email: brightway@bwwell.com for details. We will feedback at the soonest!

Email: brightway@bwwell.com

WhatsApp: +8615091866932