The Core Equipment of Slurry Separation Plant

- 2017-07-27 16:06

- Brightway Admin

-

Slurry Separation Plant(13)

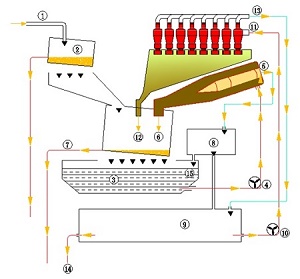

The cyclone separation system and centrifugal separation system is the key technology and core equipment of Slurry Separation Plant.

Cyclone separation system is mainly composed of cyclone desander and desilter. Firstly, the first phase separation will be done through drilling fluid shale shaker; then the separated particles will be precisely treated by the hydrocycloes into particles with different sizes.

Working Principle of Cyclonic Separation System

The mud under pressure enters the cyclone separation system with high speed through the pipe and do gyratory motion in the wall of cylinder. The coarse particles are thrown to the wall and move downward gradually by gravity and discharged from the bottom. Because of moving slowly, the fine particles is driven by the flow of liquid from the centeris and discharged from the overflow pipe.

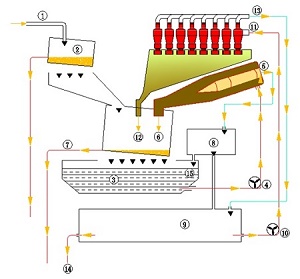

Advantages of Centrifugal Separation System

1. Centrifuges are key components to ensure that all water can be separated into dry soil. Part of bentonite processed by cyclone system can be discharged the mud pool. It will be continuing to use after mixing and saving the construction cost.

2. The particle diameter of mud is very small after processing by cyclone system. So we need to add flocculant in mud. The flocculant and fine particles aggregated the larger particles. and then it sent to the centrifuges by pump. of The solid particles separatedcan can be shipped directly. The separated water of high purity can be used to modulate the new mud or discharged into the municipal storm sewer system directly.

Know More information about Slurry Separation Plant Application and Cases:

http://www.slurrytreatmentplant.com/products/slurry-separation-plant/