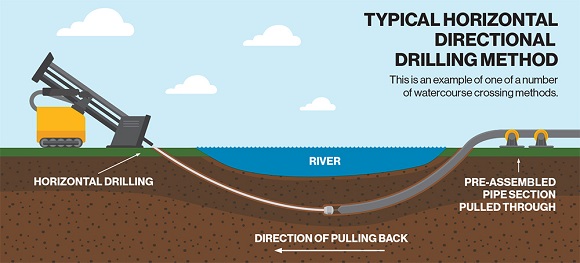

Horizontal Directional Drilling (HDD) Technology

Horizontal directional drilling (HDD) technology has obvious advantages in oil and gas pipelines crossing rivers, lakes, transportation routes, railway hubs and other obstacles and important regions. The final hole diameter of horizontal directional drilling is 1.3 ~ 1.5 times the diameter of the pipe.

Solid control principle and common methods of horizontal directional drilling.

Horizontal directional drilling through the so-called solids control (usually referred to as the solids control) process is the principle and technical method of controlling the solid particles in the mud. Through the solid control technology, remove the harmful solids in the mud, and the solid phase can be retained to meet the requirement of the slurry performance. The harmful solid phase in horizontal directional drilling mud mainly refers to the drilling cuttings that wear out and affect the rheological properties of the mud.

1.Basic principle of solid-liquid separation in horizontal directional drilling

Horizontal directional solid-phase separation follows the Stokes method which states the mathematical relationship between the small spherical particles free settling in the liquid.

V = g (rho S - rho) d2/18 eta

V -- particle deposition velocity, cm/s; D -- particle diameter, g/cm3.

G -- the acceleration of gravity, 981cm/s2; Eta -- liquid viscosity, cP.

S -- particle density, g/cm3; Rho -- liquid density, g/cm3.

The above equation is Stokes law, which is the basic formula for analyzing the separation of sedimentation tank, hydrocyclone and centrifuge.

2. Commonly used method of horizontal directional crossing mud solid control

Horizontal directional drilling in the domestic and even the world's development time is not long. There is no perfect system for drilling and mud, to a large extent, it is to absorb and apply after improving the process system used in oilfield. The solid-phase separation method of horizontal directional drilling through mud is similar to that of oilfield, which mainly has three methods: dilution, precipitation and mechanical removal.

A.Dilution: Recycle the returned mud into the mud tank, and then add water, sodium soil and additives to the required mud performance to achieve the purpose of reducing the solid content of the mud.

Advantages: Simple method, low cost.

Disadvantages: Solid phase clearance is not complete.

B.Precipitation: Dig a mud pool or more in the traversing and entry points, and return the slurry into the pool. After a natural settlement for a time, the upper liquid phase is extracted into the mud circulation and thrown to the bottom solid phase.

Advantages: Simple operation, low cost, less energy consumption.

Disadvantages: Large space occupancy, slow settling and separation speed, and the bottom solid phase hard to remove.

C.Mechanical clearance: A solid phase control system is used to separate the solid phase. The so-called solid control system, refers to the shaker screen, desander, miniature desilter and desanding cleaner, mud cleaner, centrifuge and circulating tank. According to the requirements of solid control, form a set of system. In most cases, mechanical clearance is the most effective and economical.