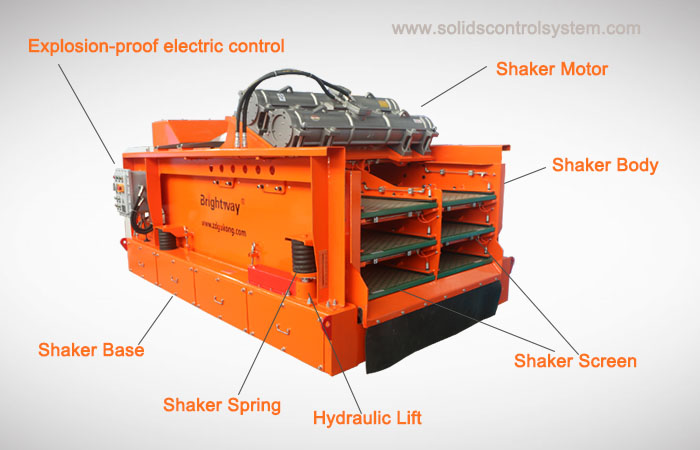

Drilling fluid shale shaker is one of the drilling solids control equipment. It is a first-phase solids control system. It consists of a shaker box, a screen, a shaker motor, an excitation beam, a shaker damping spring, a bracket, an electric control and other spare parts. Among them, spare parts such as motors, screens, springs, etc. are vulnerable parts. These parts are replaced frequently, which requires the selection of suitable spare parts for shale shakers.

The shaker motor is the core component of the shale shaker machine, that is, the shaker exciter. The size of the exciting force is determined by the size of the shale shaker, the characteristics of the material, and the processing capacity. The weight and processing capacity of the screening machine are different, so the size of the shaker motor is also different. If the exciting force is too large, the shale shaker may crack due to the excessive exciting force. On the contrary, if the exciting force is too small, the treatment effect will not be achieved, and the phenomenon of material accumulation and network blocking may occur.

The screen is an indispensable part of the shale shaker, and it is the part that is in direct contact with the material. Generally, the materials of shale shakers are divided into: composite screens, polyurethane screens, iron frame screens, stainless steel slit screens, etc. According to the different materials to be screened, different screens should be selected. Oil drilling solids control shale shakers generally use composite screens or iron frame screens, and non-excavation shields use stainless steel slit screens for shale shaker.

The shale shaker spring is a shock absorber during the shale shaker’s working process. There are steel springs, rubber springs, and gas springs. The steel springs have good toughness and are cheap, but they have high shaker noise. They are suitable for small shale shakers or simple structure shale shakers; rubber springs. The damping noise is small and durable, suitable for medium-sized shale shakers. The gas spring is mainly inflated and decompressed, with strong bearing capacity, low noise, and high price. It is suitable for the use of large multi-layer shale shakers.

The electronic control device of the shale shaker is generally supplied by the electronic control manufacturer, and the electronic components used in the electronic control system are classified into high or low levels. There are domestic brands and international brands. When choosing an electronic control device, you should choose according to the industry and budget. The electric control of the shale shaker in the oil drilling solids control industry needs explosion-proof grade, so the electronic components of the electric control are all high-quality brands, such as ABB Siemens, Schneider, etc. The requirements of the electric control device of the shale shaker in the trenchless industry are relatively low, and the general electronic components can meet the requirements.

Based on the production of traditional mud shale shakers, Brightway has designed variable frequency mud shale shakers based on the actual experience of drilling in major oil fields. The shale shaker is composed of a variable-frequency motor and a variable-frequency control system, with different conversion frequencies. It greatly expand the scope of application of the mud shale shaker and the applicable treatment medium. It is a screening equipment suitable for different viscosity requirements.

The above is a detailed introduction to the 4 important spare parts of the shale shaker. In actual use, the shale shaker spare parts should be selected according to the industry and screening media to ensure the screening effect and service life of the shale shaker.

Brightway Solids Control Co.,Ltd