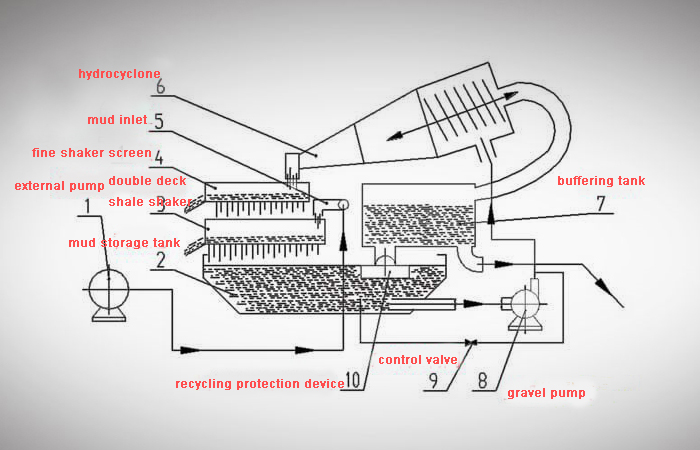

The components of slurry separation plant for tunneling is listed below

1. Slurry separation unit

The function of the slurry separation unit is to separate the clay and crushed stone mixed mud formed by the cutter head for solid-liquid separation, and achieve multi-stage control separation according to different requirements, and finally meet the mud reuse. When choosing mud water treatment equipment, two aspects must be considered: Must be able to effectively separate sand and soil in mud and control mud density; It must have the processing capacity suitable for the propulsion speed and match with the shield machine. The high-frequency dewatering shale shaker is used as the secondary solid phase control separation, and the muddy water is used as the basic screening treatment to effectively remove the agglomerated and massive coarse particles, and control the water content of the discharged solid phase (this control reduces the amount of current environmental protection requirements). It is especially important to not fall on the ground and transport) the separation of coarse particles generally adopts a double-layer or three-layer shale shaker.

2. Mud mixing unit

The mud mixing unit consists of a slurry tank, a slurry pump, a slurry agitator, a slurry storage tank, a CMS mixing tank, a CMS agitator, a CMS pump, a distribution valve and a water adding device. The CMS stirring tank stores chemical paste, and the new paste tank stores materials such as bentonite. The stirred CMS chemical paste is sent to the new paste tank for mixing and stirring to make fresh paste.

3. Mud preparation unit

The mud preparation unit consists of adjustment tank, residual tank, adjustment tank agitator, residual tank agitator, adjustment pump, residual pump, density pump, slurry pump and water adding equipment. The adjustment tank adjusts the old and new slurries, and the remaining tanks store the old and new slurries, which are stirred by agitators respectively, and the density is detected by the density pump, and then the adjusted slurry is sent to the shield mud tank by the slurry pump.

4. Mud conveying unit

The function of the mud conveying unit is to convey the adjusted mud to the shield mud water tank through the mud pump and mud pipeline to participate in the mud circulation system of the shield machine. The soil and sand cut by the cutter head and the mud water in the mud water tank are separated by the mud water treatment sub-system sent to the ground through the mud discharge pump and the mud discharge pipeline. The mud conveying unit is mainly composed of a mud feeding and discharging pump, a valve group, a mud feeding and discharging pipeline and its supporting components, etc. It is automatically operated through a mud water monitoring system.

5. Mud monitoring unit

The operation and operation of the entire slurry separation plant is realized by the mud monitoring system. The mud monitoring system is realized by PLC program. Through the application of the mud monitoring module, reliable information can be provided for shield construction at any time and the technical data of the mud-water system can be collected. The mud monitoring module monitors in five different states, such as bypass mode, tunneling mode, reverse circulation mode, isolation mode and long-time shutdown mode control.

Brightway Solids Control Co.,Ltd