Pipe-jacking Machine Working Principle

Pipe-jacking machine is the important and necessary equipment in Pipe-jacking Construction. It is the smaller diameters micro-tunnelling machine in Trenchless Construction and used to installing underground pipelines, ducts and culverts. Today , Brightway Separation Plant will talk the "Pipe-jacking machine Working Principle".

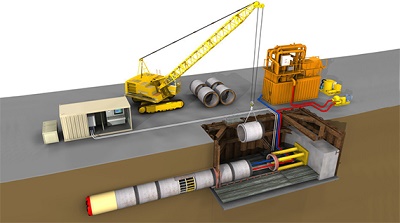

1. Pipe jacking method involves the installation of a pipe (prefabricated) through the ground. The driving takes place from a drive shaft to the reception shaft. The drive shaft consists of jacks, that moves the pipe.

2.. Powerful hydraulic jacks are used to push specially designed pipes through the ground behind a shield at the same time as excavation is taking place within the shield. The method provides a flexible, structural, watertight, finished pipeline as the tunnel is excavated.

3. During the execution of the process, the hydraulic jack makes use of thrust power to move the pipe forward into the ground. The rams of the jacks are retracted after installation of each pipe. This facilitates the preparation of next pipe in a position to repeat the same procedure.

4. The soil is transported out of the jacket pipe as well as the driven shaft, as the excavation proceeds. This is done either manually or mechanically. somtimes, the drilling slurry need the professional equipment to treatment, such as slurry separation plant, it is the important and necessary equipment to process the slurry from pipe-jacking machine.

Useful Information about Slurry Separation Plant Working Principle, you can visit :

http://www.slurrytreatmentplant.com/products/slurry-separation-plant/2.html